Quality is at the heart of what Denatec does. Driven by a passion for engineering and drawing on over 50 years of experience, Denatec strives to deliver the highest quality products and services they can. Engrained within their ethos are their customers, as they strive to achieve the highest level of excellence and take pride in building sustainable working relationships.

Inspired by innovation, Denatec aims to provide effective engineering solutions to overcome the challenges imposed by the world around us.

Quality is at the heart of what Denatec does. Driven by a passion for engineering and drawing on over 50 years of experience, Denatec strives to deliver the highest quality products and services they can. Engrained within their ethos are their customers, as they strive to achieve the highest level of excellence and take pride in building sustainable working relationships.

Inspired by innovation, Denatec aims to provide effective engineering solutions to overcome the challenges imposed by the world around us.

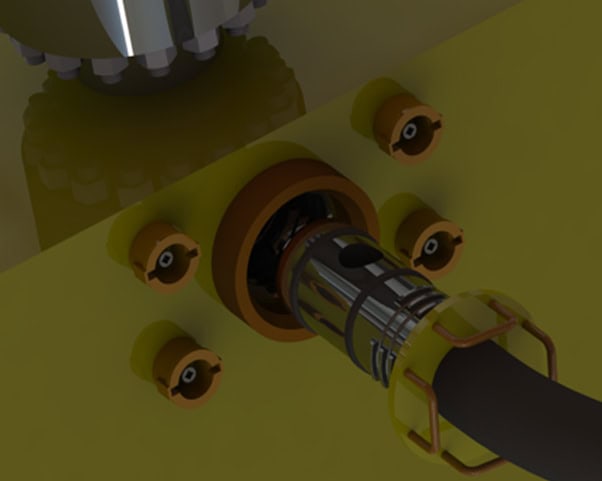

For institutes carrying out research & development (R&D) and scientific studies or companies who manufacture advanced materials, Denatec can supply High pressure, High Temperature Pressure Vessels, Reactors, Autoclaves and Isostatic Presses of any size, volume and pressure up to 60,000psi.

Designed with the client’s equipment in mind and configured to carefully manage and control each test parameter, these systems provide all the operational and safety requirements needed.